Hyperlinked-Disclaimer! You are now leaving our web site. The web site you wish to link to is owned or operated by an entity other than TONGTAI MACHINE & TOOL CO., LTD. We do not control this third party web site. We are providing this link for your convenience only and we are not responsible for the availability of or the content located on or through this third party web site, the accuracy, completeness, timeliness, or legality of any information contained in this third party web site, and any opinions expressed therein, nor for any link contained in this third party web site. This third party web site is not investigated, monitored, or checked for accuracy, completeness, timeliness, or legality, by TONGTAI MACHINE & TOOL CO., LTD. The link from our web site to this third party web site does not imply that we approve of, endorse, or recommend this third party web site. We expressly disclaim all warranties, express or implied, as to the accuracy, legality, reliability, timeliness, quality, or validity of any content on this third party web site.

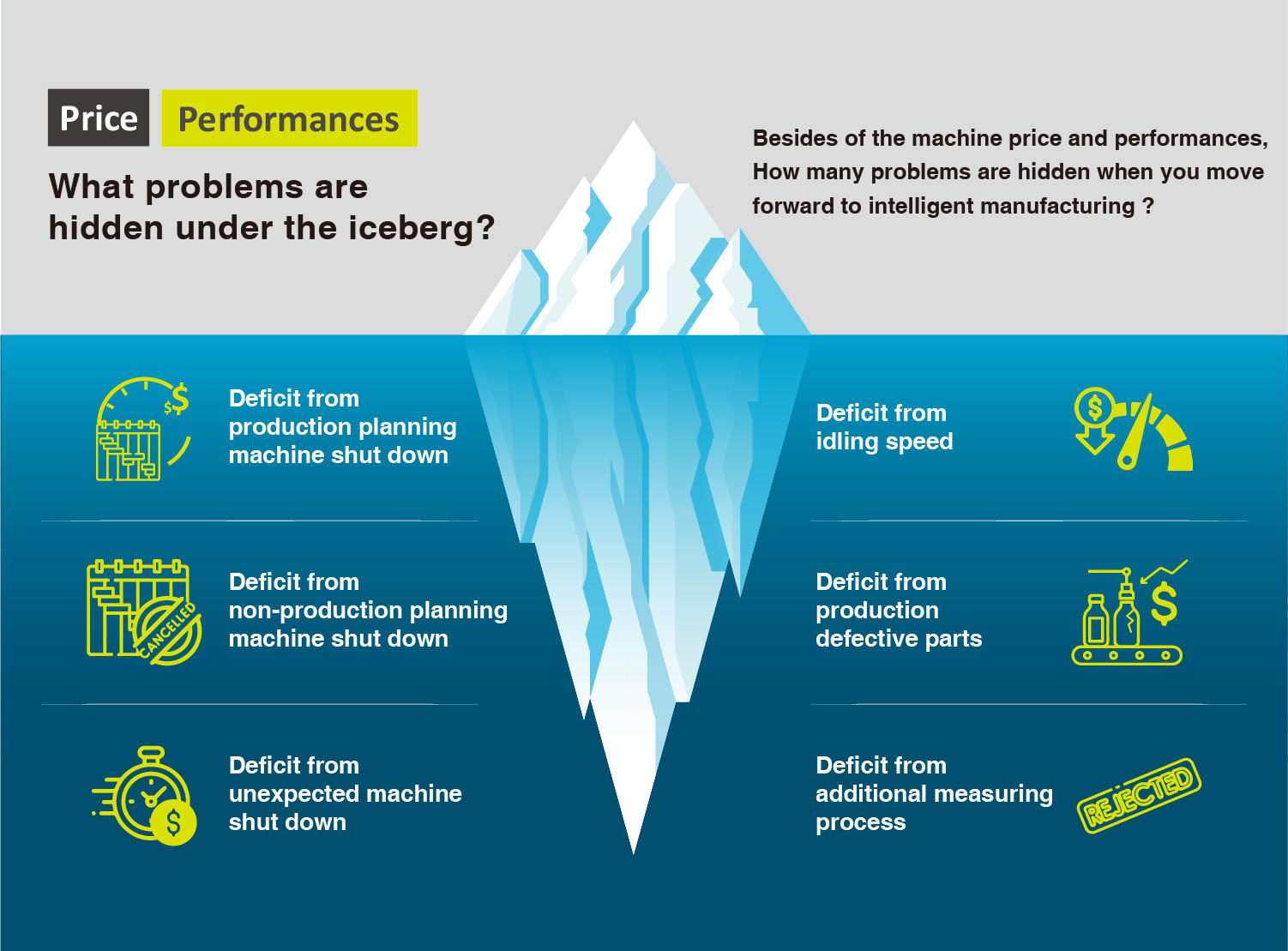

Tongtai has rich practical experience of customization which provides the best machining solutions. Through years of experience, Tongtai understands customers’ questions on the production line. In order to optimize customers’ production issues, we provided Dr.TT industrial consultation service to sort out your process first and solve your OEE (overall equipment effectiveness). If you are interested in this service, please feel welcome to contact us.

Free consultation : https://www.tongtai.com.tw/en/contact.php

Successful stories : https://www.youtube.com/playlist?list=PL9KZVUaN-uegdBuBSSLjUOHvKNE10T8sP

Dr.TT Platform

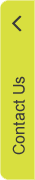

Manufacturing pain points

OEE

Standard, Optimization and Integration & Intelligence are the 3 categorizations we provided to meet customers’ various demands.

Standard

Optimization

Integration & Intelligence

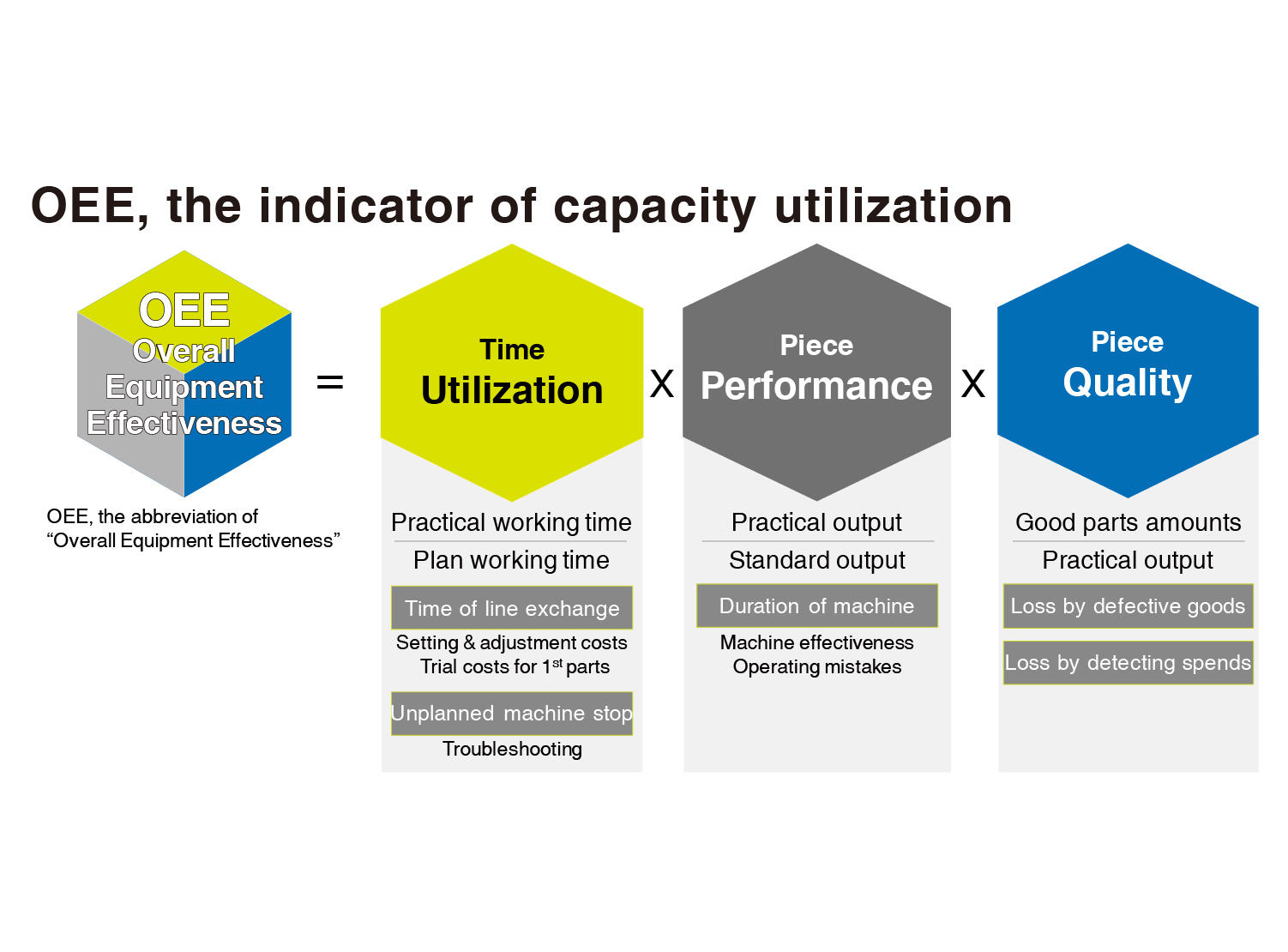

Tongtai has rich production lines, we not only provide various machine types including:: horizontal /vertical CNC lathe; horizontal/vertical machining center; multi-tasking turning center; 5 axis machine center; tapping center; ultrasonic assisted machine; and additive manufacturing equipment; but, we also provide customized functions and options that customers request.

**Customized functions and options could be consulted on with Tongtai technical team

|

|

|

|

Machines

5 axis machining

Additive manufacturing

Tongtai is famous for special purpose machines. For every customer’s specific industry and production demands, we offer optimized suggestions and suitable options to maximize their efficiency and production.

|

|

Industrial specific machine

Special purpose machine

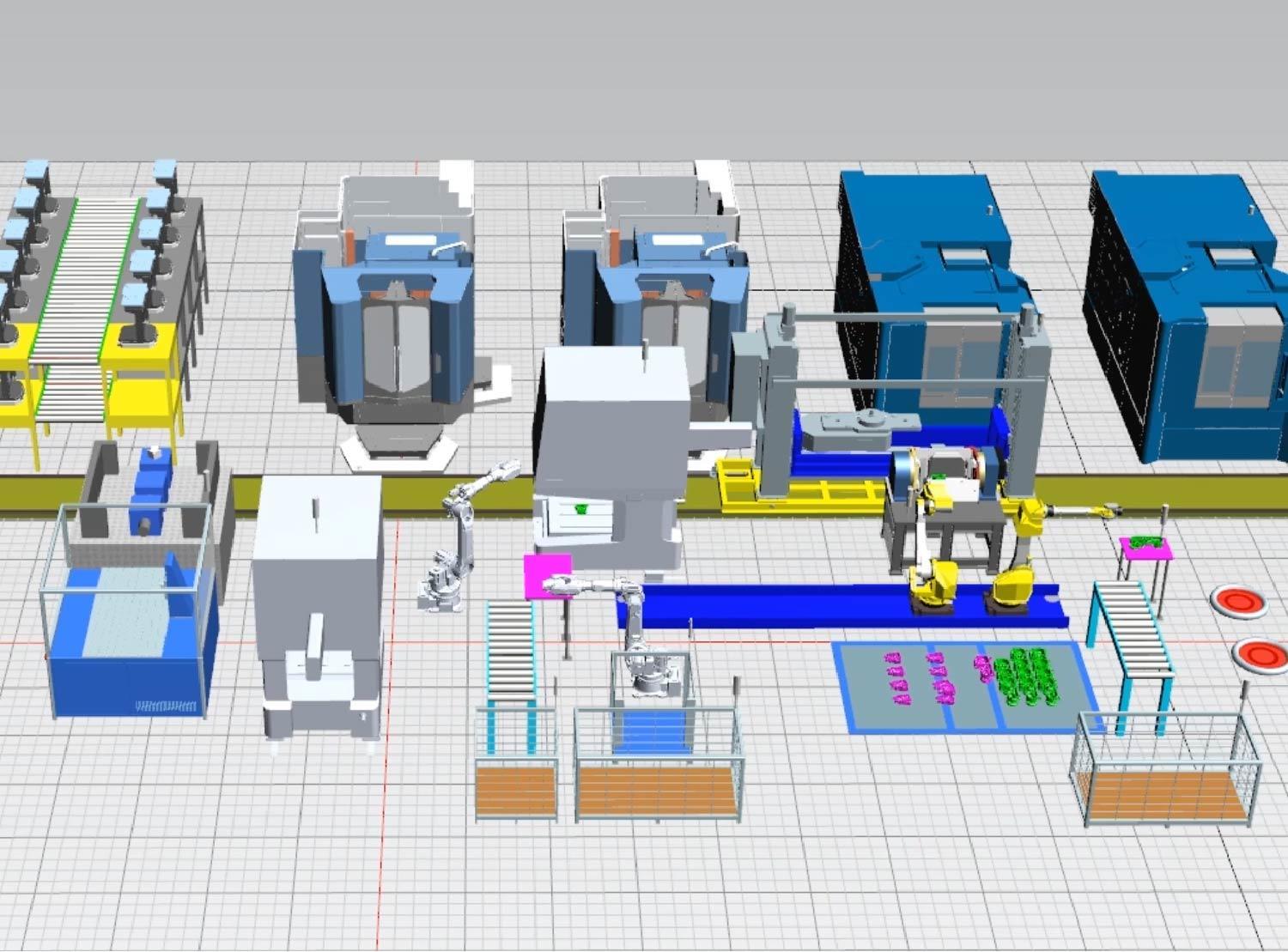

Available for various peripheral units

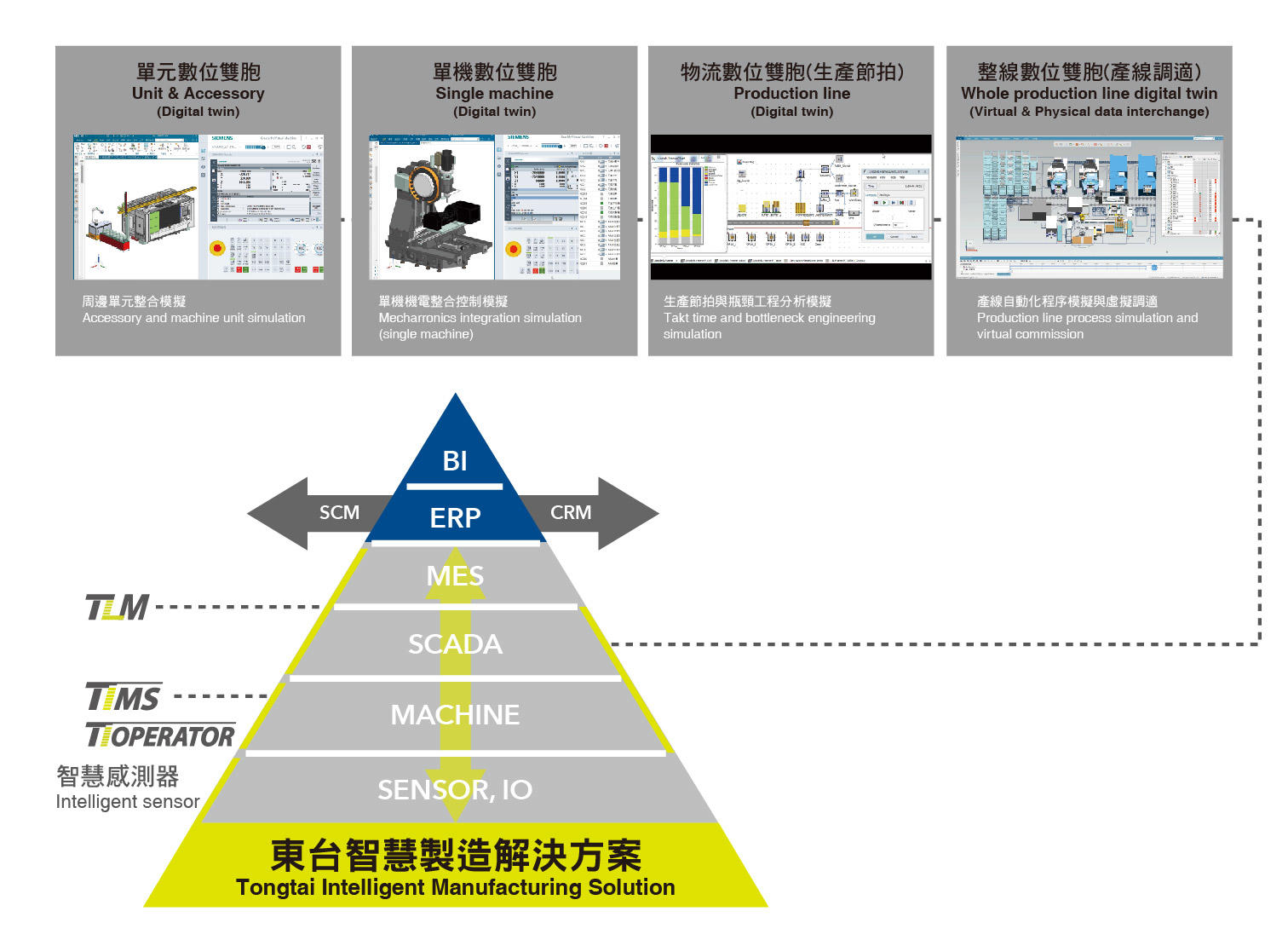

Tongtai has completed hardware / software products and service support, we assist customers to plan the production line from single to whole factory and also integrate cross-brand equipment. Moreover, “Digital Twin” will be applied at the beginning stage to assist production planning and decrease the risks of design modifications. The machining parts can be simulated before real processing to optimize the production efficiency.

|

|

|

|

CPS (Cyber-Physical System)

Wheel production line

Tongtai Intelligent manufacturing solution

Tongtai has rich experience in turnkey solutions and also provides the service of the whole production planning. Starting from the engineering analysis, we will provide suggestions for the tools, fixtures, production line planning and machining programs. Furthermore, we also do trial tests for ensuring the machine performances before the delivery to the customers.

|

Engineering Analysis & Planning |

We plan the process starting from the procedure breakdown, and satisfy the requirements of cost, quality and precision of the components. |

|

Tool Planning & Design |

Professional tool use strategies ensure that the processing time and quality fulfill all requirements. With specially designed tools, processing time can also be shortened. |

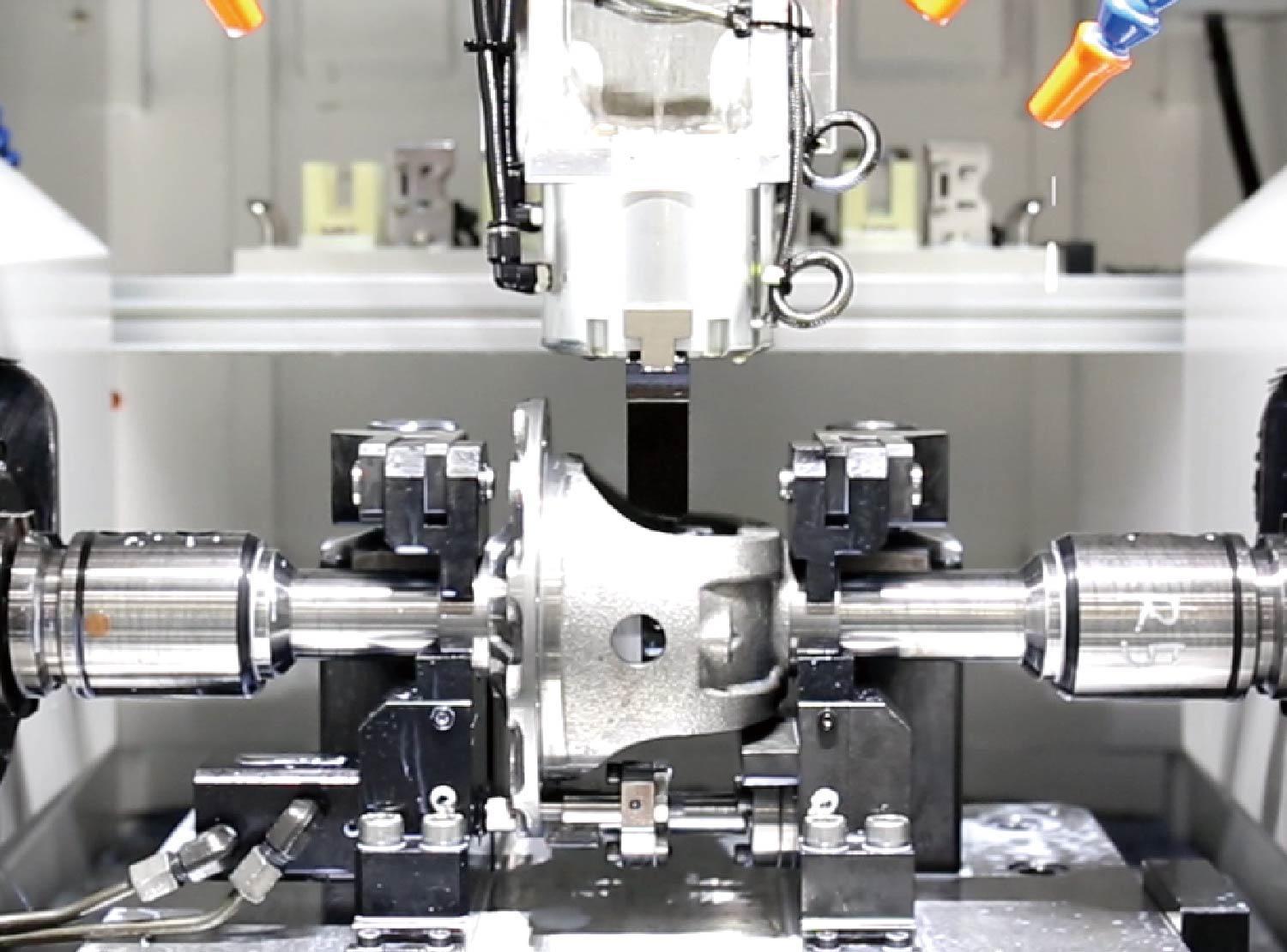

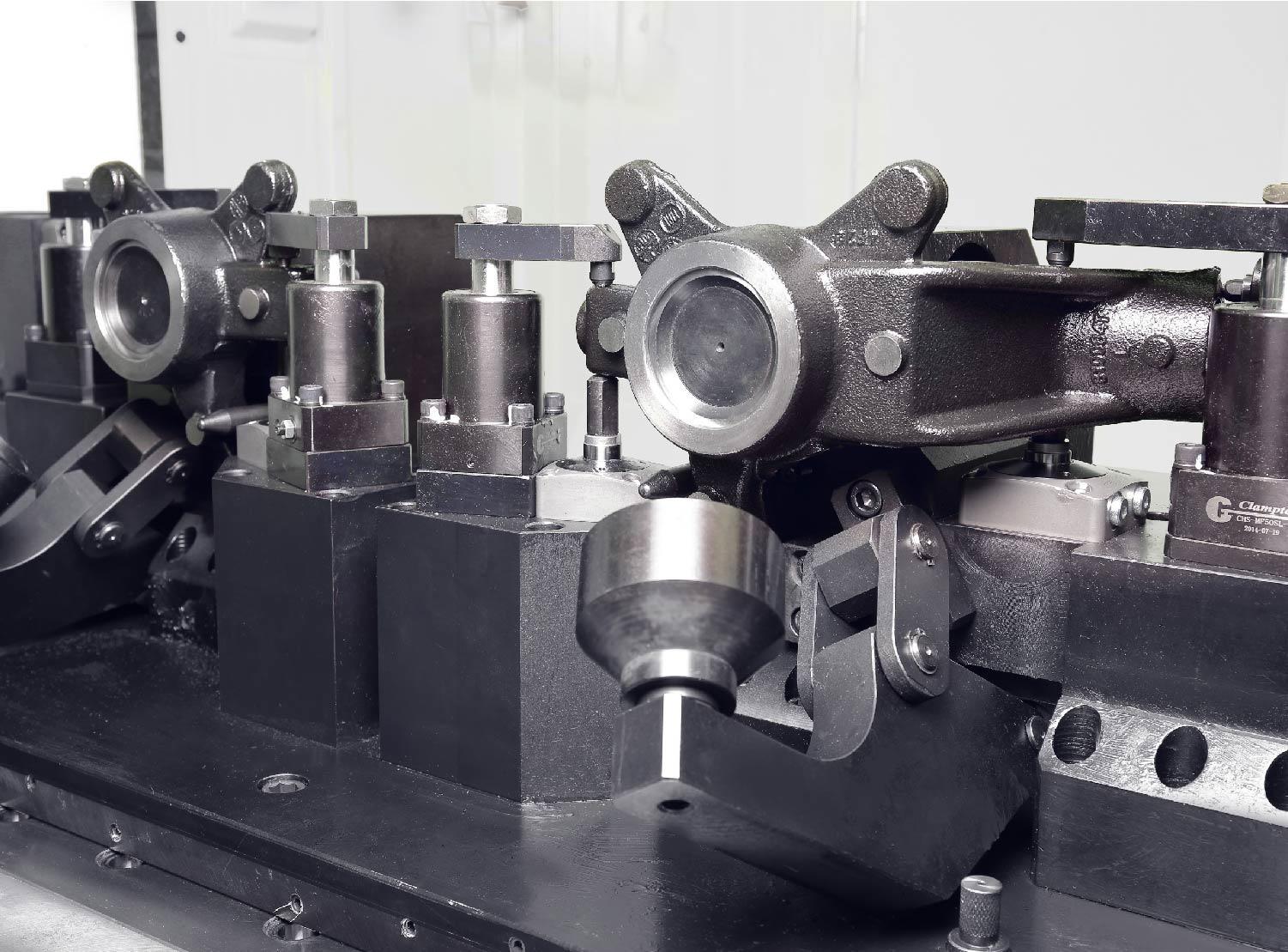

| Jig Fixture Design |

To satisfy requirements regarding processing capabilities and ensure the quality of the product, a jig fixture design that complements the machines' characteristics is required. |

|

Production Line Planning |

We choose and develop customized tools in consideration of the customer's plant size and production requirements, while providing suitable automated systems solutions for workpiece transporting, testing and cleaning. We design a production line best suited to our customer. |

|

Process Planning Programming |

We find the most optimized route and adjust equipment parameters, based on the tools and fixture designs to achieve optimized processing efficiency. |

|

Batch Trial Production and Verification |

We satisfy all customers' demands, concerning geometric accuracy, roughness and cycle time. We verify the suitability of our designs through quality testing and CPK verification. |

Engineering consulting

Customized fixture

Wheel production line