Hyperlinked-Disclaimer! You are now leaving our web site. The web site you wish to link to is owned or operated by an entity other than TONGTAI MACHINE & TOOL CO., LTD. We do not control this third party web site. We are providing this link for your convenience only and we are not responsible for the availability of or the content located on or through this third party web site, the accuracy, completeness, timeliness, or legality of any information contained in this third party web site, and any opinions expressed therein, nor for any link contained in this third party web site. This third party web site is not investigated, monitored, or checked for accuracy, completeness, timeliness, or legality, by TONGTAI MACHINE & TOOL CO., LTD. The link from our web site to this third party web site does not imply that we approve of, endorse, or recommend this third party web site. We expressly disclaim all warranties, express or implied, as to the accuracy, legality, reliability, timeliness, quality, or validity of any content on this third party web site.

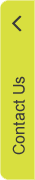

By leveraging a tool's high frequency vibration (15-45kHz) and its maximum rotation speed (24,000 RPM), a new machining technique is achieved well suited for working with hard & brittle materials processed via grinding and pounding. Cutting stress is reduced by 30% to 70% when the tool/grinding rod comes into contact with the material (based on different material properties), thus extending the tool life as well as enhancing surface quality.

Up to 24,000 rpm

Greatly decreases cutting stress

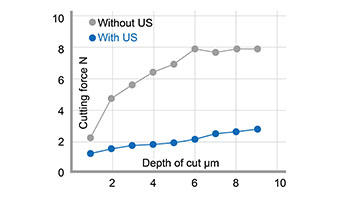

Through ultrasonic assisted machining techniques, hard & brittle materials can be processed easily with minimized clipping size.

Processing of hard & brittle materials such as glass

No clipping on contour processing

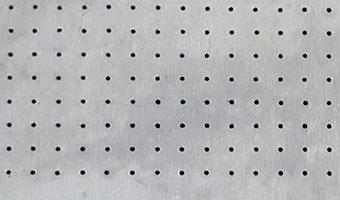

Increases the tool life by reducing cutting resistance. By using 0.5mm precision hole drilling in silicon wafers, as an example, tool life is increased from 3 to 236 holes drilled.

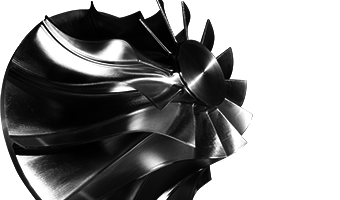

0.5mm silicon wafer micro drills

Diamond tools

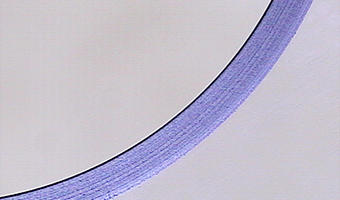

Through ultrasonic assisted machining, surface roughness can reach Ra 0.2 μm, greatly reducing the time required for polishing process.

Immaculate striation surface processing of aluminum alloys

Finishing process of aluminum alloys reaches precision of Ra 0.2 μm

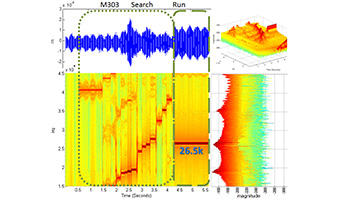

Excellent ultrasonic control technology ensures the processing stability under long durations. Through operating the machine controller's M-code, we can easily execute movements such as automatic frequency scanning, frequency choosing, power adjustment, and switching the ultrasonic on/off, controls

Automatic frequency scanning

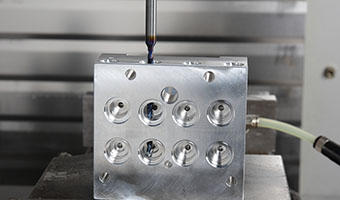

Adopt BBT tool system to first do rough processing with standardized tools. Then turn on the ultrasonic function to do finish processing with ultrasonic tool holders. These procedures can greatly increase operating efficiency.

Applicable standard tools

Can be applied to medical, molding, high tech ceramic, glassware, automobile and aerospace industries.

Biomedical

High-tech ceramics

Glassware, jewelry processing

Automobile finishing process

Finished surface processing for aerospace industries

Finished surface processing for molding industries